At SG Medical we perform quality control at all stages: from receiving raw materials to final inspection and packaging. We maintain traceability by creating lot numbers at entry level or at manufacturing stages (Serial or Lots). Constant inspections are performed throughout the entire process and recorded on the Device History Record (DHR).

SG Medical works continuously towards enhancing the quality and the affordability of the devices by investing in the manufacturing capital and by providing continuous training, clear Work Instructions (WI), Specifications, Drawings, Inspections, DHR, BOM and DMR.

We use advanced technologies such as reflowing, gluing, soldering, welding, cutting, heat shrinking, packaging, lean manufacturing and logistics.

Technologies

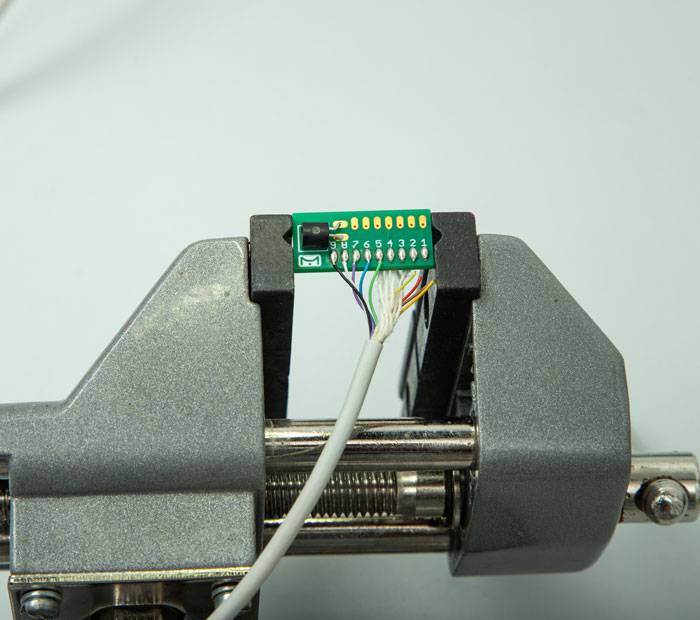

The assembly of complex catheters is a main area of expertise at SG Medical. Our skilled hand assemblers work under microscopes to meet the customers’ high level of requirements, using micro tools to connect small components from 50 μm to 3mm range. Our operators can manipulate extra small wires, cables, tubes, electrodes and connect them with different techniques used in complex catheter’s manufacturing.

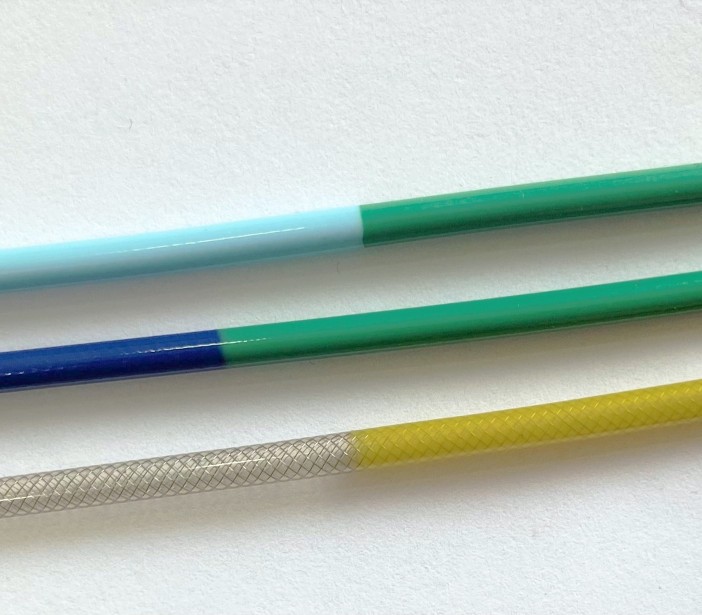

SG Medical offers reflowing technology to reinforce catheter’s tubing wall with metal braid, which is ideal for medical devices that require strength, torque transmission, crush resistance, kink resistance, compression resistance and to maintain flexibility.

We also help our customers reach the perfect shaft for their catheter by offering several sections (different material, different dimension, with/ without braid…).

SG Medical offers reflow capabilities ranging from 0.75 French (Fr) to 32 Fr outside diameter shafts.

The following design parameters may be changed to develop the desired catheter shaft:

- Liner and Jacket Material (Pebax, Nylon, PTFE, PET, FEP…)

- Braid Material (Nitinol, Stainless Steel, Vectran, Kevlar)

- Braid Pattern (1 wire under 1 over 1, 1 wire under 2 over 2, 2 wire under 2 over 2)

- Braid or Coil Shape (round wire, flat wire)

- Multiple sections with different hardness and composition over the catheter length Coils integration within shaft layers

Our professional angle or square cuts will ensure that your pre-fuse segments will reflow correctly with minimal felt transition zones.

SG Medical has a long expertise in fusing different material together using heaters and laminators.

SG Medical offers the following bonding options:

- IR/UV Adhesive Gluing

- Heat Welding/ Staking

- Adhesive Bonding: Epoxy, Cyanoacrylate...

- Optical Fiber Gluing with nano displacement

SG Medical can glue small fibers inside small catheters with range starting from 72 μm fibers

The bonding is assessed with high standard controls (tensile testing, optical and visual inspection, leak testing).

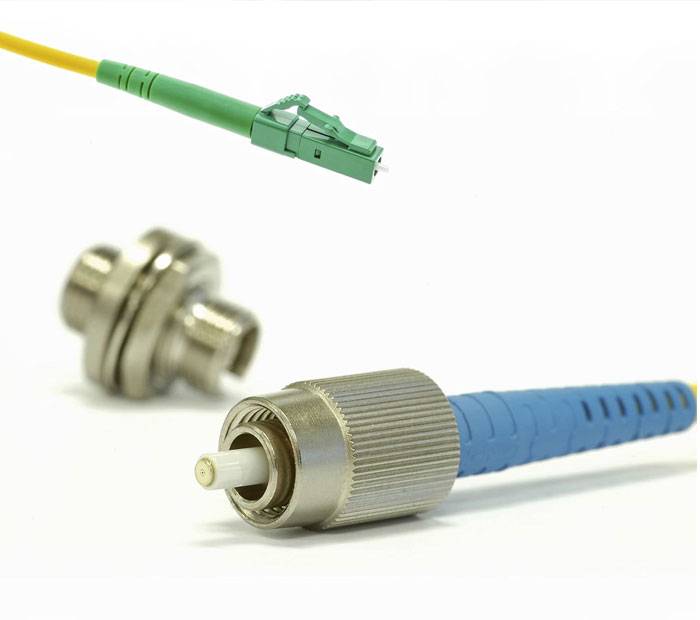

SG Medical offers its assistance with every step of optical connectorization to improve the quality of the light wave transmission:

- Fiber cleaving

- Fiber stripping connector assembly

- Optical polishing

We are capable of soldering complex circuits (PCB) as well as high precision connectors that are used in complex devices. Soldering uses ROHS components and meets medical device regulations standards.

SG Medical is able to perform high precision axial and longitudinal cut on several medical device components.

Shaft and tubes cutting are some examples of our long-term expertise.

We are able to cleave optical fibers with the high level of precision required in optical connectrorization.

Our coating process guarantees a clean and consistent coating application.

With the support of our suppliers, we can develop device specific durable and lubricious coatings.

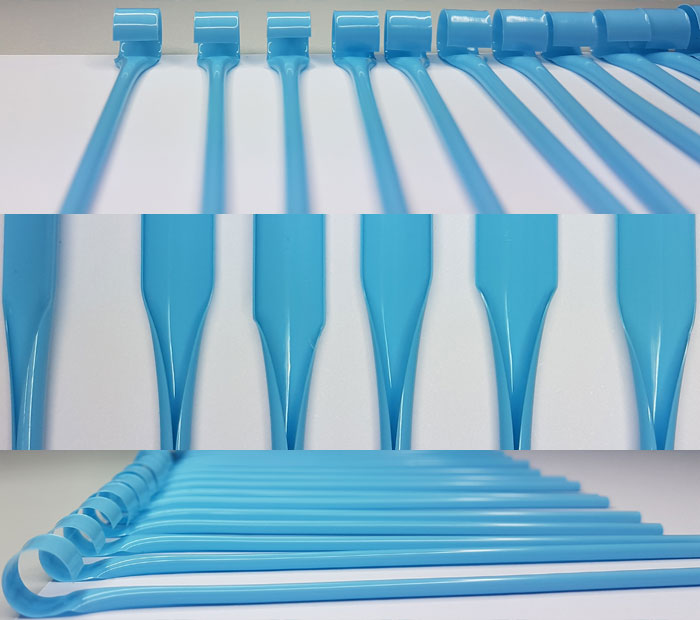

Our packaging services are performed in ISO class 7 environments by our trained technicians.

We also coordinate testing and validate packaging under a proven quality system.

We partner with industry leaders to provide a smooth turnkey solution.

Our packaging services include :

- Cards, coils, and trays

- Tyvek, nylon, foil, and combination pouches

- Pouch and tray sealers

- Labelling including IFUs, bar codes

SG Medical has a great range of QA tests that comply with catheters norms such as ISO 10555 (Mechanical: tensile, torque, buckling, steering tests, irrigation leakage).

Packaging testing and validation: SG Medical can perform packaging tests that comply with global regulations (MDR, FDA) to guarantee the integrity of your device packaging and ensure that it remains sterile until the point of use.

Chemical stripping is performed to uncoat wires, fibers and thermocouples.